Useful Info

Useful Information

- Private Wells

- Septic Tank

- Swimming Pools

- Indoor Air Quality

- Water Testing

- Aluminum Wiring

- What is Polybutylene?

Properly constructed private water supply systems require little routine maintenance. These simple steps will help protect your system and investment.

- Always use licensed or certified water well drillers and pump installers when a well is constructed, a pump is installed or the system is serviced.

- An annual well maintenance check, including a bacterial test, is recommended. Any source of drinking water should be checked any time there is a change in taste, odor or appearance, or anytime a water supply system is serviced.

- Keep hazardous chemicals, such as paint, fertilizer, pesticides, and motor oil far away from your well.

- Periodically check the well cover or well cap on top of the casing (well) to ensure it is in good repair.

- Always maintain proper separation between your well and buildings, waste systems or chemical storage facilities. Your professional contractor knows the rules.

- Don't allow back-siphonage. When mixing pesticides, fertilizers or other chemicals, don't put the hose inside the tank or container.

- When landscaping, keep the top of your well at least one foot above the ground. Slope the ground away from your well for proper drainage.

- Take care in working or mowing around your well. A damaged casing could jeopardize the sanitary protection of your well. Don't pile snow, leaves, or other materials around your well.

- Keep your well records in a safe place. These include the construction report, as well as annual water well system maintenance and water testing results.

- Be aware of changes in your well, the area around your well, or the water it provides.

- When your well has come to the end of its serviceable life (usually more than 20 years), have your qualified water well contractor properly decommission your well after constructing your new system

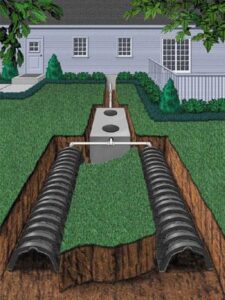

Everything that goes down any of the drains in the house (toilets, showers, sinks, laundry machines) travels first to the septic tank. The septic tank is a large-volume, watertight tank which provides initial treatment of the household wastewater by intercepting solids and settleable organic matter before disposal of the wastewater (effluent) to the drain field.

FUNCTION OF THE SEPTIC TANK

While relatively simple in construction and operation, the septic tank provides a number of important functions through a complex interaction of physical and biological processes. The essential functions of the septic tank are to: receive all wastewater from the house separate solids from the wastewater flow cause reduction and decomposition of accumulated solids provide storage for the separated solids (sludge and scum) pass the clarified wastewater (effluent) out to the drain field for final treatment and disposal.

Primary Treatment

As stated, the main function of the septic tank is to remove solids from the wastewater and provide a clarified effluent for disposal to the drain field. The septic tank provides a relatively quiescent body of water where the wastewater is retained long enough to let the solids separate by both settling and flotation. This process is often called primary treatment and results in three products: scum, sludge, and effluent.

Scum: Substances lighter than water (oil, grease, fats) float to the top, where they form a scum layer. This scum layer floats on top of the water surface in the tank. Aerobic bacteria work at digesting floating solids.

Sludge: The "sinkable" solids (soil, grit, bones, unconsumed food particles) settle to the bottom of the tank and form a sludge layer. The sludge is denser than water and fluid in nature, so it forms a flat layer along the tank bottom. Underwater anaerobic bacteria consume organic materials in the

sludge, giving off gases in the process and then, as they die off, become part of the sludge.

Effluent: Effluent is the clarified wastewater left over after the scum has floated to the top and the sludge has settled to the bottom. It is the clarified liquid between scum and sludge. It flows through the septic tank outlet into the drain field.

HOW LONG LIQUIDS MUST REMAIN IN TANK

Effective volume: The floating scum layer on top and the sludge layer on the bottom take up a certain amount of the total volume in the tank. The effective volume is the liquid volume in the clear space between the scum and sludge layers. This is where the active solids separation occurs as the wastewater sits in the tank.

Retention time: In order for adequate separation of solids to occur, the wastewater needs to sit long enough in the quiescent conditions of the tank. The time the water spends in the tank, on its way from inlet to outlet, is known as the retention time. The retention time is a function of the

effective volume and the daily household wastewater flow rate:

Retention Time (days) = Effective Volume (gallons)/Flow Rate (gallons per day)

A common design rule is for a tank to provide a minimum retention time of at least 24 hours, during which one-half to two-thirds of the tank volume is taken up by sludge and scum storage. Note that this is a minimum retention time, under conditions with a lot of accumulated solids in the tank. Under ordinary conditions (i.e., with routine maintenance pumping) a tank should be able to provide two to three days of retention time. As sludge and scum accumulate and take up more volume in the tank, the effective volume is gradually reduced, which results in a reduced retention

time. If this process continues unchecked-if the accumulated solids are not cleaned out (pumped) often enough-wastewater will not spend enough time in the tank for adequate separation of solids, and solids may flow out of the tank with the effluent into the drain field. This can result in clogged pipes and gravel in the drain field, one of the most common causes of septic system failure.

SOLIDS STORAGE

In order to avoid frequent removal of accumulated solids, the septic tank is (hopefully) designed with ample volume so that sludge and scum can be stored in the tank for an extended period of time. A general design rule is that one-half to two-thirds of the tank volume is reserved for sludge and scum accumulation. A properly designed and used septic system should have the capacity to store solids for about five years or more. However, the rate of solids accumulation varies greatly from one household to another, and actual storage time can only be determined by routine septic tank inspections.

ANAEROBIC DECOMPOSITION

While fresh solids are continually added to the scum and sludge layers, anaerobic bacteria (bacteria that live without oxygen) consume the organic material in the solids. The by-products of this decomposition are soluble compounds, which are carried away in the liquid effluent, and various gases, which are vented out of the tank via the inlet pipe that ties into the house

plumbing air vent system. Anaerobic decomposition results in a slow reduction of the volume of

accumulated solids in the septic tank. This occurs primarily in the sludge layer but also, to a lesser degree, in the scum layer. The volume of the sludge layer is also reduced by compaction of the older, underlying sludge. While a certain amount of volume reduction occurs over time, sludge

and scum layers gradually build up in the tank and eventually must be pumped out.

FLOW INTO AND OUT OF THE TANK

The inlet and outlet ports of the tank are generally equipped with devices such as baffles, concrete tees, or in more recent years, sanitary tees (T-shaped pipes with one short and one long leg).

Inlets

The inlet device dissipates the energy of the incoming flow and deflects it downwards. The vertical leg of the tee extends below the liquid surface well into the clear space below the scum layer. This prevents disturbance of the floating scum layer and reduces disruptive turbulence caused by incoming flows. The inlet device also is supposed to prevent short-circuiting of

flows across the water surface directly to the outlet. The upper leg of the inlet should extend well above the liquid surface in order to prevent floating scum from backing up into, and possibly plugging, the main inlet pipe. The open top of the inlet tee allows venting of gases out of the tank through the inlet pipe and fresh air vents of the household plumbing.

Outlets

The outlet device is designed to retain the scum layer within the tank. A sanitary tee can be used with the lower leg extending below the scum layer. The elevation of the outlet port should be 2 to 3 inches below the elevation of the inlet port. This prevents backwater and stranding of solids in the main inlet pipe during momentary rises in the tank liquid level caused by surges of incoming wastewater.

Typical inlet/outlet tees

Gas Deflection Baffle

Gases are produced by the natural digestion of sludge at the bottom of the tank, and particles of sludge can be carried upward by these rising gases. Some tanks have a gas deflection baffle, which prevents gas bubbles (to which solid particles often adhere) from leaving the tank by deflecting them away from the outlet and preventing them from entering the drain field.

THE EFFLUENT FILTER

In newer systems, there is often an effluent filter: one of the significant improvements in septic tank design in decades. They range from 4 to 18 inches in diameter. As we have described, the most serious problem with septic systems is the migration of solids, grease, or oil into the

drain field, and the filter is effective in preventing this. A filter restricts and limits passage of suspended solids into the effluent. Solids in a filtered system's effluent discharge are significantly less than those produced in a non-screened system.

FLOW BUFFERING

The septic tank also provides a buffering of flows between the house and the drain field. Large surges from the household, such as toilet flushing or washing machine drainage, are dampened by the septic tank so that the flows leaving the tank and entering the drain field are at substantially lower flow rates and extend over a longer period of time than the incoming surges.

MICROBES IN SEPTIC TANKS DIGEST, DISSOLVE, AND GASIFY COMPLEX ORGANIC WASTES

In 1907, W. P. Dunbar conducted tests on the decomposition of vegetable and animal matter in septic tanks. He stated, "The author has investigated the subject by suspending in septic tanks a large number of solid organic substances, such as cooked vegetables, cabbages, turnips, potatoes, peas, beans, bread, various forms of cellulose, flesh in the form of dead bodies

of animals, skinned and unskinned, various kinds of fat, bones, cartilage, etc., and has shown that many of these substances are almost completely dissolved in from three to four weeks. They first presented a swollen appearance, and increased in weight. The turnips had holes on the surface,

which gradually became deeper. The edges of the cabbage leaves looked as though they had been bitten, and similar signs of decomposition were visible in the case of other substances. Of the skinned animals, the skeleton alone remained after a short time; with the unskinned animals the process lasted rather longer. At this stage I will only point out that the experiments were so arranged that no portion of the substances could be washed away; their disappearance was therefore due to solution and gasification."

This information can clarify and help answer some questions.

Pool types: Pools are available in two types: above ground and in-ground. The type can determine the amount and kind of cleaning methods.

Pool materials: Pools come in a variety of different materials, some requiring more maintenance than others.

Fiberglass is used for a one-piece tub fitted into a pre-dug hole. The slick surface repels algae, but it will need occasional re-coating.

Concrete is covered with a plaster water seal that can take more wear and tear than other pool materials. It'll probably need to be replaced every 7 to 10 years.

Aggregate finish is a concrete pool with a specialized finish that has better traction. It's covered with a layer of embedded rounded gravel.

Tile is a concrete pool with a tile finish instead of a plaster finish. The tile surface requires less surface maintenance than other surfaces.

The slick surface of a vinyl liner, like fiberglass, repels algae.

Pool problems: How much your pool is used will help determine the amount of cleaning needed. For instance, murky or colored water may mean you have chemical imbalances, pollutants such as microorganisms, or a clogged filter. Clogged filters can mean money down the drain.

Algae can be another spoiler. It needs to be attacked two ways -- through chemical treatment, and a lot of filtering, backwashing, scrubbing, and skimming. Whether it is green, brown, or little black spots of algae, it will take over your pool if it is not dealt with immediately.

Features: Pools can have several features that can affect your cleaning job. Many larger pools have heaters, especially those installed in cooler climates. Many homeowners turn off the heater in the warmer months to save on the utility bill. Your filtration system keeps the water clean.Improper chemical balances open the door to contamination, therefore it?s also advisable to use a water testing kit. It gives a good indication when you need temporary treatment, and when a pool service professional is needed.

Some manual pool covers are designed for safety to keep kids out of the water in case they slipped on the edge. Winter covers can also lower your heating and chemical use. It's a nice feature to keep leaves and bugs at a minimum.

An automatic pool cover is just like a manual pool cover, except a machine rolls it back and forth along tracks. There is more to cleaning a pool, however, than keeping a proper pH balance. Not only is there skimming for floaties, but also vacuuming; scrubbing the tiles, sides, and floor; and cleaning, maintaining, emptying, and backwashing the filter and pump. A professional pool cleaning service will give you many clean, clear hours free of scale, rust, pollutants, bacteria and cloudy water. (But it?s up to you to watch for that occasional leaf.)

If you own an outdoor pool in a climate that gets cold during the winter, many experts strongly suggest you winterize your pool. Winterization usually entails draining most of the water, blowing out the pipes, applying algaecide and antifreeze in key areas, and covering the pool. Winterization will protect your pool from any freeze damage that can harm your pool surface and equipment.

One sure path to energy efficiency in houses is eliminating air leaks. If you cut down the amount of air that has to be heated and cooled, you cut your utility bill substantially. But plugging up all those air leaks means less fresh air inside and this has brought on other problems.

One of the first to be identified was elevated concentrations of volatile organic compounds in the air. Commonly called VOC's, these compounds are used in the manufacture of the many synthetic building products used in most new houses today, including carpeting, flooring, paint, cabinetry, countertops, and the structural framework itself. Hundreds of off-gassing VOC's have been identified, but the one that has captured the most attention is formaldehyde. It is a potent eye and nose irritant and causes respiratory effects. It is also classified by the US Government Environmental Protection Agency as a probable human carcinogen.

In response to the concerns raised by health officials and the public over the last fifteen years, manufacturers of some building materials and furnishings have altered their chemical formulations, significantly reducing the amount of VOC's off gassing from their products.

A brand new house will still have a significant amount of VOC's in the air because the rate at which the VOC's off-gas is highest initially. This phenomenon accounts for the "new house smell" that most new house buyers experience. Delaying a move-in and airing out a house by opening all the windows and running all the exhaust fans will benefit the occupants, even if this is done for only two days, advised John Girman, Director of the Center for Analysis and Studies for the Indoor Environmental Division of the US Government Environmental Protection Agency.

Continuing to keep the windows open and ventilating the house for several day to several weeks, if weather permits, can also be beneficial, added Al Hodgson of Lawrence Berkeley National Laboratory in Berkeley, California, who has been studying indoor air quality for the last 18 years.

After the first month or so, the rate at which the VOC's off gas from building materials may fall off, but Hodgson's research indicates that the off-gassing phenomenon will continue at a slow and steady pace for months or even years. Hodgson measured the indoor air quality in eleven new, but unoccupied houses one to two months after their completion. Some were monitored over a period of about nine months. Overall he found that the concentrations of VOC's in the houses were not "alarming," although the concentrations of some compounds were high enough to produce an odor. The levels of formaldehyde were too low to have a smell, but high enough to cause discomfort in some individuals.

Although the level of VOC's in new houses does fall off over time, buyers can reduce it at the outset by their selection of finishes. Hodgson's research has shown while carpets are generally low emitters of VOC's, a reasonable quality, medium-grade, nylon, certified green label carpet may emit less than the basic grade carpet that most builders offer as standard. Installing the carpet with tack strips instead of an adhesive eliminates a potential VOC source altogether. Synthetic fiber carpet padding emits less than the rebonded padding that most production builders provide.

Hodgson's "certified green label carpet" refers to the green and white Carpet and Rug Institute emission test sticker found on carpeting that meets their emission standard. Their testing program was established after sensational stories about "killer carpets" appeared in newspapers and TV news programs in the early nineties. In a New England lab, mice were exposed to carpet samples and subsequently died. Scientists in other labs including the EPA were never able to replicate these results and the reason for the mice's demise remains unclear.

After the Carpet and Rug Institute started its carpet-testing program, it raised the emission standards, which has further reduced carpet emissions. Even so, carpeting can still have an odor that makes people think that they are being exposed to something awful, Hodgson observed.

Vinyl flooring is a stronger emitter than carpet, but it too should not be a cause for concern, Hodgson said.

The oil-based alkyd and water-based latex paints used in most houses are another source of VOC's. The alkyds, which create a harder, more washable surface, are usually used for bathrooms, kitchens, and the trim around doors, windows and baseboards. They produce a terrible smell and emit hundreds of VOC compounds, but these are almost entirely dissipated after about 48 hours, said John Chang, of the EPA labs in Triangle Park, North Carolina. The latex paints have a different smell and emit only four or five VOC compounds, but these continue to off gas for days and weeks after the paint is dry. "Low VOC" latex paints are now available, but some of these emit formaldehyde and buyers should check the paint emission data, he advised.

Hodgson is currently studying the man-made wood products used in residential construction because most of them contain formaldehyde, and formaldehyde concentrations in the indoor air of new houses have been found to be higher than in other building types. Large quantities of these wood products including cabinet materials, doors, door and window trim and baseboards are found in the finished space of new houses. Man-made wood products are also used extensively in their structural framework. Hodgson is looking at the emissions of formaldehyde and VOC's from each product as well as the amount of exposed surface of each product. He is finding that bare surfaces of wood products can have relatively high emissions, but that surfaces with laminate and vinyl finishes generally have low emissions.

In some cases, products that are considered to be low emitters are turning out to be a significant source of VOC's when viewed in the context of the whole house, Hodgson said. For example, formaldehyde and other VOC's given off by the oriented strand board or plywood used for the subfloor in most new houses today are low when calculated on a square foot or a per piece basis. But Hodgson's research is showing that when the total area of the subflooring in a typical house is taken into account, it can be a significant VOC source and that the overlying carpet and carpet padding are not effective barriers.

Other research in indoor air quality in new houses has focused on the problem of underventilation. Until the last 20 years or so, mechanical engineers could reasonably assume that between air leaks and occupants opening the windows, everyone was getting plenty of fresh air. But as houses have become tighter, less outside air is penetrating through air leaks and with air conditioning; no one opens the windows in the summer anymore.

To rectify this situation, the American Society for Heating, Refrigeration, and Air Conditioning Engineers, commonly known as ASHRAE, proposes that mechanical ventilation be required in all new houses, as it is in most commercial and office buildings. The engineers have not dictated how this should be accomplished, and the desired ventilation rate varies with the size of the house and the number of bedrooms. For a 2,400 square-foot house with four bedrooms, for example, the proposed rate would be .35 changes per hour. At this rate, all the air in the house would be replenished every threehours.

Some homebuilders have suggested that ASHRAE's ventilation proposal could add $1,500 to $6,000 to the cost of a new house, but ASHRAE's proposal could be easily and inexpensively done. One continuously running 100 cfm bathroom exhaust fan that is exhausted to the outside would do the job for a 2,400 square foot house and this modification would cost only $75 to $100 more than the exhaust fan and venting that the builder would already be installing in the bathroom, said Max Sherman, also of the Lawrence Berkeley National Laboratory, who has studied indoor air for 20 years. Putting a smaller continuously running fan in each bathroom is a more expensive solution, but it would distribute the fresh air more evenly.

The ASHRAE proposal includes a sound recommendation for the continuously running fan because occupants turn fans off when they're too noisy. The dedicated exhaust fan should have a sound level of one sone or less so that it won't disturb a household at night when the ambient noise level is low.

Relocating the air-handling unit from the garage to some other place in the house would also improve indoor air quality, Sherman said. In some parts of the country such as Florida and California, houses do not have basements and the air handling equipment is often put in the garage. Unfortunately the ducts for the system often leak so that if a car engine is left running for any length of time, homeowners can unwittingly introduce carbon monoxide into their living areas.

Water is the universal solvent, and it has the capability of dissolving just about anything.

Because of this unique property, water can easily become contaminated. Serious contaminates such as Lead and E. Coli Bacteria may be toxins affecting your family’s health. Listed below are the four major testing categories that we can examine when doing a water test.

Inorganic—Minerals and physical properties Organic—Petroleum products, gasoline, fuel oil, and solvents

Microbiology—Coliform and other bacteria Radiology—Radon gas Test Options

1. Standard Test includes Microbiology and Inorganic.

2. Comprehensive Test includes all four testing categories: inorganic, organic, microbiology, and radon. The comprehensive test is good way to start. It is a powerful tool in detecting contaminants commonly found in surface and deep well waters.

3. If you are suspicious of pesticides or herbicides, the Comprehensive Plus Pesticides test is recommended.

We can also test for individual items such as Lead in Water.

Due to implications in numerous house fires, the once common practice of using aluminum wiring during the 1970's is no longer permitted in new installations in most jurisdictions. If your house has aluminum wiring you do not necessarily need to panic. Aluminum wiring can be just as safe as copper wire as long as it has been installed correctly. The concern with aluminum wiring is that it is very unforgiving if it has been installed incorrectly.

Aluminum wiring expands when it warms up, and contracts then it cools down. Aluminum reacts differently than copper wire after several warm/cooling cycles. After each cycle aluminum tends to lose more of its tightness. This process is often referred to as "cold creep". Combined with aluminum's tendency to oxidize when in contact with certain metals, these factors can lead to dangerous problems. When aluminum oxidizes it heats up more to conduct the same amount of electricity, which then causes more oxidation. Due to this cycle, eventually the wires may start to get very hot, melt the fixture that it attached to, and even possibly cause a fire.

If you are considering purchasing a home with aluminum wiring, or have discovered it later, it would be a good idea to hire a licensed electrician or inspector to check over the wiring for any potential problems.

Polybutylene is a form of plastic resin that was used extensively in the manufacture of water supply piping from 1978 until 1995. Due to the low cost of the material and ease of installation, polybutylene piping systems were viewed as "the pipe of the future" and were used as a substitute for traditional copper piping. It is most commonly found in the "Sun Belt" where residential construction was heavy through the 1980's and early-to-mid 90's, but it is also very common in the Mid Atlantic and Northwest Pacific states.

The piping systems were used for underground water mains and as interior water distribution piping. Industry experts believe it was installed in at least 6 million homes, and some experts indicate it may have been used in as many as 10 million homes. Most probably, the piping was installed in about one in every four or five homes built during the years in which the pipe was manufactured.

How to Tell If You Have Poly

Exterior - Polybutylene underground water mains are usually blue, but may be gray or black (do not confuse black poly with polyethelene pipe). It is usually 1/2" or 1" in diameter, and it may be found entering your home through the basement wall or floor, concrete slab or coming up through your crawlspace; frequently it enters the home near the water heater. Your main shutoff valve is attached to the end of the water main. Also, you should check at the water meter that is located at the street, near the city water main. It is wise to check at both ends of the pipe because we have found cases where copper pipe enters the home, and poly pipe is at the water meter. Obviously, both pipes were used and connected somewhere underground.

Interior - Polybutylene used inside your home can be found near the water heater, running across the ceiling in unfinished basements, and coming out of the walls to feed sinks and toilets. Warning: In some regions of the country plumbers used copper "stub outs" where the pipe exits a wall to feed a fixture, so seeing copper here does not mean that you do not have poly.

Will the Pipes Fail?

While scientific evidence is scarce, it is believed that oxidants in the public water supplies, such as chlorine, react with the polybutylene piping and acetal fittings causing them to scale and flake and become brittle. Micro-fractures result, and the basic structural integrity of the system is reduced. Thus, the system becomes weak and may fail without warning causing damage to the building structure and personal property. It is believed that other factors may also contribute to the failure of polybutylene systems, such as improper installation, but it is virtually impossible to detect installation problems throughout an entire system.

Throughout the 1980's lawsuits were filed complaining of allegedly defective manufacturing and defective installation causing hundreds of millions of dollars in damages. Although the manufacturers have never admitted that poly is defective, they have agreed to fund the Class Action settlement with an initial and minimum amount of $950 million. You'll have to contact the appropriate settlement claim company to find out if you qualify under this settlement.